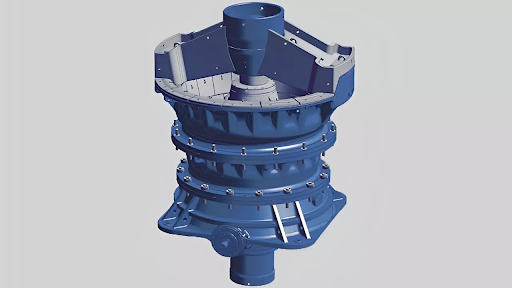

Gyratory crushers are one of the most popular and versatile machines used in the mining and construction industries. Popular for their effectiveness and capacity to reduce big volumes of substances into smaller ones, these crushers are very essential in most operations. In this article, we will introduce the working principle, the types, and the application of the gyratory crushers, and also recommend JXSC which is a famous mining equipment manufacturer.

What is a Gyratory Crusher

A gyratory crusher is one of the main types of primary crushers used in mining and ore processing industries and features a circular cross-section. It is made of a concave face and a conical head both of which are made of manganese steel. The crushing action takes place when the mantle within the crusher gyrates and applies the pressure on the material to be crushed against the concave.

The gyratory crusher is used to reduce the size of hard materials with a reduction ratio of one on one, that is, it can reduce large rocks into smaller sizes in one operation. This makes it suitable for use in the primary crushing stage especially in the operations that involve mining and quarrying.

Also Read

5StarsStocks.com Passive Stocks | FintechZoom

How Does it Work

The operation of a gyratory crusher involves the crushing of large sized ores between two structures known as the stationary and the moving structures. During operation of the machine, the motor rotates the eccentric bushing that in turn rotates the central shaft. This is due to the fact that as the shaft turns the mantle approaches the concave surface and crushes the material. The material is then compressed down through the crushing chamber until it has been reduced to the right size.

Due to the continuous operation of the gyratory crusher, it is capable of handling large quantities of material in the shortest time possible. While in operation, gyratory crushers work in a constant motion while jaw crushers work on an oscillating motion which makes gyratory crushers ideal for operations that require high production rates.

Types of Gyratory Crushers

Some of the variations include; Gyratory crushers are available in several types, designed for different purposes. The following are the most common types:The following are the most common types:

Primary Gyratory Crusher

The primary gyratory crusher is used in the initial stage of crushing where very large sizes of materials are fed through the crusher. It is intended for the processing of large and tough materials and is suitable for large scale mining or quarrying operations. These machines are suitable for operations that entail constant crushing of large amounts of material for long periods.

Secondary Gyratory Crusher

Although both types of machines are of similar design, secondary gyratory crushers are used for further reduction of materials after primary crushing. These crushers are useful in producing smaller materials for other processes in industries or to prepare materials for other processes in tertiary crushers.

Cone Crusher vs. Gyratory Crusher

Due to the working principle of the machines, the gyratory crusher is often compared with cone crushers. Both machines are used for compression but the main difference is that gyratory crushers are often used for primary crushing while cone crushers are used for secondary and tertiary crushing. Gyratory crushers are generally of higher capacity and can handle larger sizes of material and hence are used for heavy duty operations.

Benefits of Using Gyratory Crushers

Gyratory crushers have several advantages, which makes them suitable for use in many industries. These benefits include:

– High Capacity: Gyratory crushers are suitable when volume is a concern not only because they can crush a lot at once but also due to their large size.

– Continuous Operation: While some crushers employ a stop-and-start operation, gyratory crushers are constantly working and thus more productive and efficient.

– Uniform Crushing: The pressure applied in a gyratory crusher is constant and this makes the final product to be of a standard size, this is suitable for applications where the size of the material is very important.

– Durability: These machines are designed to take the abuse of heavy usage in harsh environments. As for maintenance, a gyratory crusher can achieve good performance for many years as long as it is well maintained.

Industrial Applications

Gyratory crushers are used in different industries and in different applications. Some of the most common uses include:Some of the most common uses include:

– Mining: Gyratory crushers are widely used in the mining industry for the purpose of crushing raw ore into smaller sizes which are suitable for other processes. Due to their hardness and abrasion resistant properties they are suitable for use in mining industries.

– Construction: In construction, gyratory crushers are used in breaking down large rocks and aggregates for use in concrete and asphalt among others.

– Quarrying: These machines are used in the quarries to crush large quantities of rocks and stones which are then transported or further processed.

– Chemical Industry: In the chemical industry, gyratory crushers are used to crush raw materials that are used in production to ensure that they are of the right size for further processing.

To explore more about the machinery and equipment used in various industrial applications, you can visit this link:https://www.jxscmachine.com/id/kategori/pemisah-magnetik/

JXSC: A Reliable Provider of Gyratory Crushers

As for the choice of the right gyratory crusher for the project, one should always rely on the trustworthy supplier. JXSC is a professional mining equipment manufacturer with rich experience in the production of mining and crushing equipment. JXSC provides various types of primary and secondary gyratory crushers, which include cone crusher, jaw crusher, impact crusher, and hammer crusher.

JXSC has been in the business of producing high-quality gyratory crushers that can withstand the harshest environments. Being an innovative and customer-oriented company, they supply equipment that will guarantee high performance in mining, quarrying and construction sectors.

Gyratory crushers are widely used in various industries especially in mining and construction industries. This makes them so important in these sectors because they are capable of processing large amounts of hard materials. This paper will discuss the different types of gyratory crushers and their applications and help industries make the right decision in choosing the right machine. Thus, industries can be assured of getting the right gyratory crusher from reputable providers such as JXSC for their operations.

More Read About: